About Us

Led By the best

Some engineers follow, others lead. Michael L. Moore has been on the cutting edge of innovation for over 30 years. When Michael worked for a major airline and the overhauled engines kept returning to the shop, Michael re-engineered a nozzle guide vane for a major engine. When the turbine blades kept failing he designed a fix that was adopted by the OEM. Michael has been working the hot section of aircraft engines for 30 years, constantly looking for ways to improve the parts operating in this hot environment. Michael was a consultant to NASA for five years on hot sections.

Michael Moore is an Aerospace and Metallurgical Engineer and a FAA Designated Engineering Representative (DERT-RS) for almost 30 years. He worked as the Senior Vice President of Research and Development helping to start and grow one of the largest PMA companies.

There is one thing that everyone that knows Michael Moore knows and that is he does not cut corners. Michael operates with “belts and suspenders”; he says when engineers fail lives are lost. He will not compromise quality for price.

Michael is the CEO and lead engineer.

35 Years of Experience

Why Choose Us

Continual Process Improvements and Dedication to Safety

Our engineers are trained to constantly look for process improvements, understand the operating environment of the parts and work with a “safety first” attitude. Innovation for improved parts and safe operating conditions. We design repairs or new parts only after knowing the detailed engineering data related to the OEM Parts including the base material, the coatings, the exact dimensions and the operating environment. Our repairs are designed to re-engineer and improve the parts.

3 T’s, Technical Data, Training & Tools

Engineering ensures that the repair shop has all necessary equipment to perform the majority of the repair in-house.

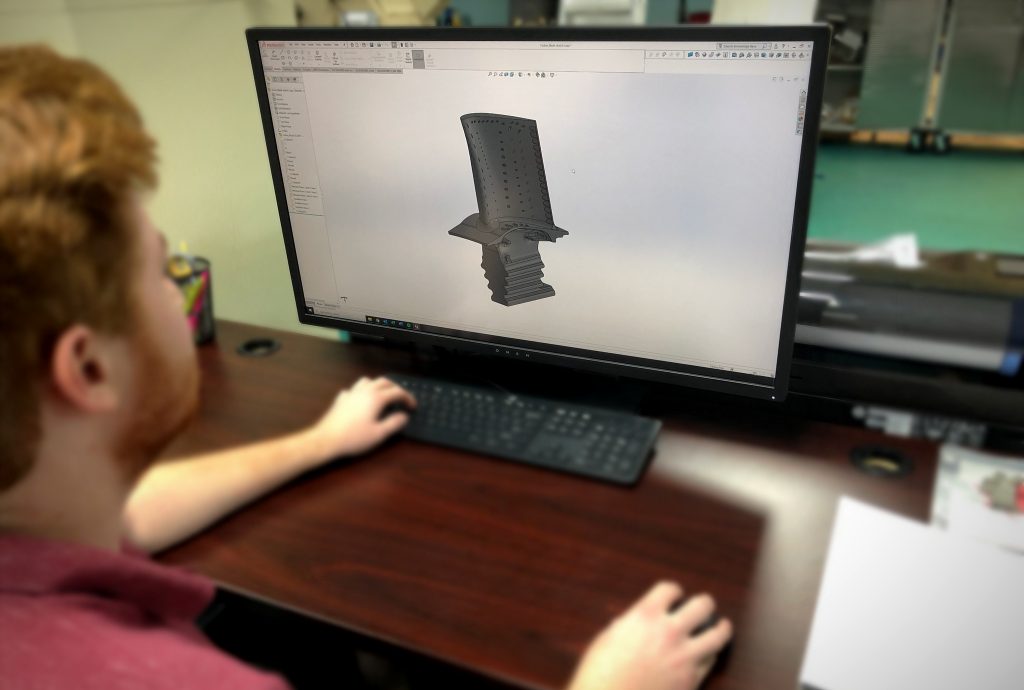

The engineering group works with state of the art design software, electron beam microscope, material analysis equipment, laser scanning equipment to determine the original design data for both repairs and PMA’s. Then they look for improvements based on proven data from newer designs or military applications.

competitive Pricing

As a smaller shop with in-house design capacity, we can be more efficient. Our pricing is a significant discount to the OEM or larger repair shops. Our motto is Quality, Pricing and Service.